According to a recent industry report, nearly 70% of construction projects exceed their budgets, and 75% miss their completion deadlines. These failures aren’t just numbers—they represent real costs, both financial and reputational. As someone who has witnessed the chaos of poorly managed construction sites firsthand, I can tell you that effective project management in civil engineering isn’t just important—it’s essential.

During my early career days, I remember visiting a bridge construction site where timeline estimates had been wildly optimistic and coordination between teams was practically non-existent. Watching skilled engineers struggle with preventable problems made me realize how crucial structured project management actually is in turning designs into reality.

In this post, we’ll explore five key project management strategies that can transform how civil engineering projects are executed, helping students and early-career professionals bridge the gap between theoretical knowledge and practical application.

Understanding Project Management in Civil Engineering: The Foundation of Success

Project management in civil engineering goes far beyond scheduling and budgeting. It’s the comprehensive process of planning, organizing, securing, and managing resources to achieve specific engineering goals within defined constraints.

Think about what happens on a typical construction site: multiple contractors working simultaneously, materials arriving daily, permits requiring approval, and stakeholders expecting regular updates. Without effective project management, this complexity quickly devolves into costly chaos.

Why does this matter so much in civil engineering specifically? Because our projects tend to be:

- Physically massive (buildings, bridges, highways)

- Extremely expensive (often millions or billions of dollars)

- Long-duration (months or years, not weeks)

- Highly regulated (building codes, environmental requirements)

- Publicly visible and scrutinized

- Directly impacting public safety

When a software project fails, a company might lose money. When a civil engineering project fails, people’s safety could be at risk, communities might be disrupted, and enormous resources might be wasted.

What Makes Project Management Different in Civil Engineering?

Civil engineering project management requires a unique blend of technical engineering knowledge and management skills. You need to understand both the structural integrity requirements of a foundation and how to manage the team installing it.

The stakes are also higher. While all projects face challenges, civil engineering projects often deal with immovable constraints like weather conditions, site-specific challenges, and rigid regulatory requirements that can’t be negotiated away.

Key Takeaway: Project management in civil engineering combines technical expertise with management skills to coordinate complex projects with high public visibility and safety implications. It’s not an add-on skill but a core competency for successful civil engineers.

Strategy 1: Mastering the Project Lifecycle

The civil engineering project lifecycle follows a structured approach that helps manage complexity through distinct phases. Understanding these phases is crucial for maintaining control throughout the project.

Initiation: Getting It Right From the Start

The first phase sets the foundation for everything that follows. During initiation, you’ll:

- Define project goals and objectives (using SMART criteria)

- Identify key stakeholders and their expectations

- Develop a business case and feasibility studies

- Secure initial approvals and funding

I once worked on a project where we rushed through this phase to “save time.” The result? We had to revisit fundamental questions mid-construction, causing delays that cost far more than the time we thought we were saving.

Planning: Where Success Truly Begins

The planning phase is where you create your roadmap. This includes:

- Developing a detailed Work Breakdown Structure (WBS)

- Creating a schedule with realistic timelines

- Estimating costs and establishing a budget

- Identifying required resources

- Establishing quality standards

- Developing risk management strategies

The WBS deserves special attention. By breaking down the project into manageable components—think of it as creating a detailed recipe for your project—you create clarity about what needs to be done and who’s responsible. This prevents the common problem of tasks “falling through the cracks.”

Execution: Bringing Plans to Life

During execution, you’ll:

- Coordinate team activities and resources

- Implement quality control measures

- Manage stakeholder communications

- Process change requests

- Document progress and issues

This phase is where your leadership skills become particularly important. Teams need clear direction, timely decisions, and effective conflict resolution.

Monitoring and Controlling: Staying on Track

This phase happens concurrently with execution and involves:

- Tracking actual progress against the plan

- Monitoring costs against the budget

- Implementing corrective actions when needed

- Managing scope changes through a formal process

- Conducting regular risk assessments

One particularly effective technique is earned value management (EVM), which allows you to measure project performance objectively. EVM helps you answer crucial questions like “Are we behind schedule?” and “Are we over budget?” with concrete data rather than impressions.

Closure: Finishing Strong

The final phase includes:

- Completing all deliverables

- Getting final approvals

- Releasing resources

- Documenting lessons learned

- Transitioning to operations

Many teams neglect proper closure, eager to move on to the next project. This is a mistake. The lessons learned during a project are invaluable for improving future performance.

Key Takeaway: Each phase of the project lifecycle serves a specific purpose. Rushing through or skipping phases typically leads to problems later. Investing time in thorough planning and diligent monitoring pays dividends throughout the project’s life.

Strategy 2: Leveraging Tools and Technology for Project Control

The days of managing projects with just paper plans and spreadsheets are long gone. Today’s civil engineering projects demand sophisticated digital tools to manage their complexity.

Project Management Software: Digital Command Centers

Modern project management tools give teams unprecedented visibility and control. Here’s a comparison of popular options:

| Software | Best For | Key Features |

|---|---|---|

| Microsoft Project | Medium to large projects | Comprehensive scheduling, resource management, familiar interface |

| Primavera P6 | Large, complex projects | Multi-project management, risk analysis, industry standard for major infrastructure |

| Procore | Construction-specific needs | Field management, quality control, RFI tracking |

| Asana/Trello | Team collaboration | User-friendly interfaces, task assignment, better for smaller projects |

The key is choosing software that matches your specific project needs. For smaller projects, lighter tools like Asana might be sufficient. For complex infrastructure projects, robust solutions like Primavera P6 are often necessary.

According to a Construction Management Association of America report, projects that utilize specialized software experience 35% fewer delays and 25% fewer budget overruns.

BIM: Bringing Designs to Life Before Breaking Ground

Building Information Modeling (BIM) has transformed how civil engineering projects are planned and executed. Unlike traditional 2D plans, BIM creates detailed 3D models containing information about every project component.

Think of BIM as creating a virtual twin of your project before construction begins. This digital approach offers several game-changing benefits:

- Clash detection: Finding conflicts between systems (like when a beam would hit a duct) before construction begins

- Better visualization: Helping clients see exactly what they’re getting

- 4D scheduling: Linking models with timelines to visualize construction sequences

- 5D cost estimation: Getting more accurate material quantities and costs

- Improved coordination: Creating one source of truth for all teams

On a recent highway overpass project, our BIM model caught a utility conflict that would have cost weeks of delays if discovered during construction. The upfront modeling time paid for itself many times over.

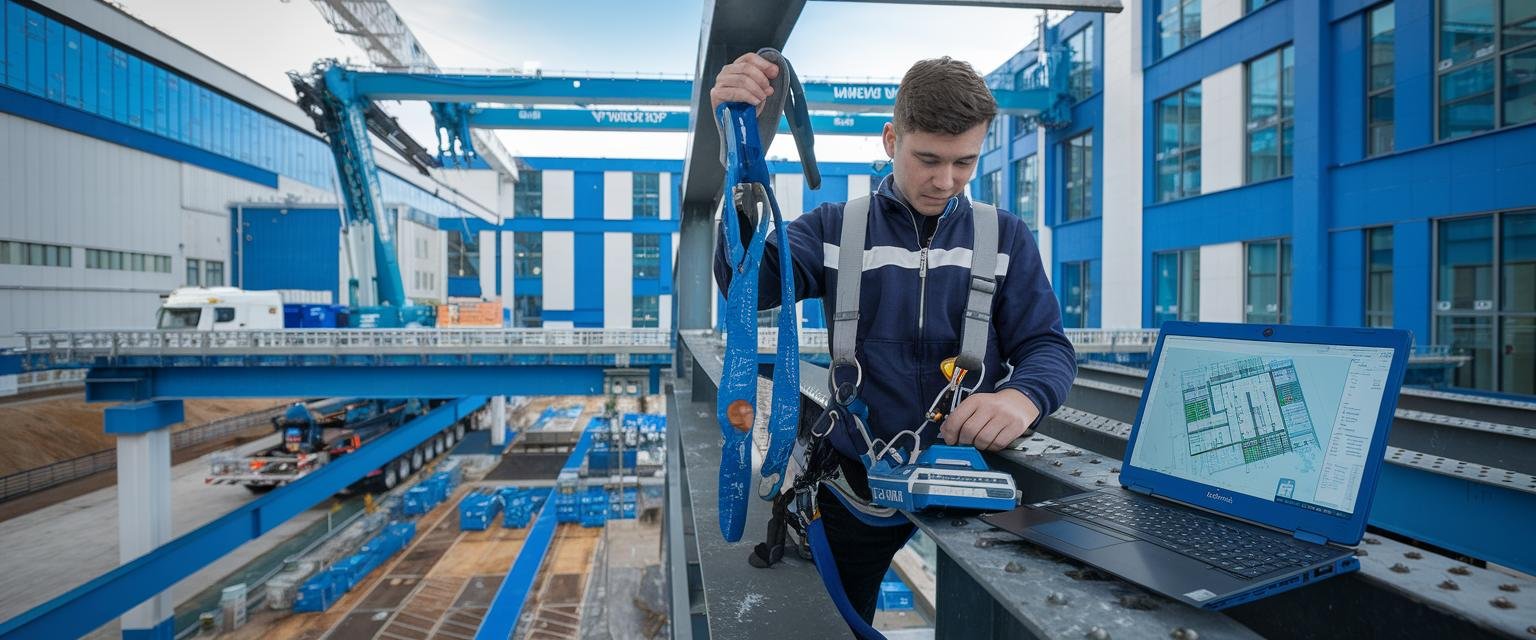

Mobile Technologies: Taking Management to the Field

Today’s project managers aren’t tied to the office. Mobile technologies enable:

- Real-time progress updates from the field

- On-site access to plans and specifications

- Photo and video documentation of issues

- Immediate communication with team members

- Digital sign-offs and approvals

Tools like PlanGrid and FieldWire have made it possible to carry entire sets of construction documents in your pocket and mark up changes in real-time.

Key Takeaway: The right technology stack can dramatically improve project visibility, coordination, and control. Invest time in selecting appropriate tools and training your team to use them effectively. The initial learning curve is far outweighed by long-term efficiency gains.

Strategy 3: Embracing Sustainability in Project Management

Sustainability isn’t just a buzzword—it’s becoming a fundamental requirement in civil engineering projects. Effective project managers now integrate sustainable practices throughout the project lifecycle.

The Triple Bottom Line Approach

Modern project management considers three key dimensions:

- Economic sustainability: Ensuring the project makes financial sense not just in construction but throughout its lifecycle

- Environmental sustainability: Minimizing negative environmental impacts

- Social sustainability: Creating positive outcomes for communities and addressing stakeholder concerns

This approach requires thinking beyond initial construction to consider the entire lifecycle of the structure or infrastructure being built.

Practical Sustainability Strategies

Here are specific ways to incorporate sustainability into your project management approach:

- Materials selection: Choose recycled, renewable, or locally sourced materials when possible

- Energy efficiency: Design for reduced energy consumption during both construction and operation

- Waste reduction: Implement construction waste management plans to minimize landfill impact

- Water conservation: Incorporate systems for rainwater harvesting, greywater reuse, and efficient fixtures

- Site impact minimization: Protect natural features and reduce disruption to local ecosystems

One particularly effective approach is to pursue certification under systems like LEED (Leadership in Energy and Environmental Design) or Envision, which provide frameworks for sustainable infrastructure.

According to the U.S. Green Building Council, LEED-certified buildings typically use 25-30% less energy and 15% less water, while generating significant waste reduction.

Measuring and Reporting Sustainability Performance

What gets measured gets managed. Consider implementing:

- Carbon footprint tracking

- Construction waste diversion rates

- Energy modeling and performance tracking

- Water usage monitoring

- Post-occupancy evaluations

These metrics help quantify the impact of sustainability initiatives and provide valuable data for future projects.

Key Takeaway: Sustainability is no longer optional in civil engineering project management. By integrating sustainable practices from the beginning, you can reduce environmental impact, lower lifecycle costs, and create more value for stakeholders.

Strategy 4: Mastering Communication and Stakeholder Management

I’ve seen technically excellent projects fail because of poor communication. In civil engineering, where multiple stakeholders have different (and sometimes conflicting) priorities, communication isn’t just important—it’s everything.

Identifying and Analyzing Stakeholders

Start by mapping all stakeholders and their interests:

- Client/owner

- Design team

- Construction contractors and subcontractors

- Regulatory authorities

- End users

- Community members

- Utility companies

- Financial institutions

For each stakeholder, assess:

- Their level of interest in the project

- Their level of influence

- Their primary concerns and expectations

- Preferred communication methods and frequency

This analysis helps prioritize communication efforts and tailor messages appropriately. For example, on a recent municipal project, we identified that local business owners were highly concerned about construction disrupting customer access. By recognizing this early, we created a phased construction plan that minimized impact on business hours and maintained clear access signage throughout the project.

Developing a Communication Management Plan

A formal communication plan prevents information gaps and ensures stakeholders receive the information they need. Include:

- Communication objectives

- Stakeholder analysis

- Communication methods and frequency

- Roles and responsibilities

- Distribution methods

- Feedback mechanisms

Different stakeholders need different information. For example:

- Clients need progress updates, cost information, and decision requests

- Team members need detailed instructions, schedules, and technical information

- Regulatory authorities need compliance documentation

- Community members need information about impacts and benefits

Managing Conflict Effectively

Conflict is inevitable in complex projects. Effective project managers:

- Address issues promptly before they escalate

- Focus on interests rather than positions

- Use data to ground discussions

- Document agreements and follow up

- Know when to escalate to higher authorities

I once managed a project where neighboring property owners were concerned about construction noise. Instead of dismissing their concerns, we worked with them to adjust work hours and implement additional noise mitigation measures. This proactive approach prevented potential legal challenges that could have delayed the project.

Building Trust Through Transparency

Trust is built through consistent, honest communication—even when the news isn’t good. When problems arise (and they always do), communicating them promptly along with a plan to address them maintains stakeholder confidence.

Key Takeaway: Effective communication requires planning, not just talking. Develop a communication strategy tailored to each stakeholder’s needs and consistently deliver on your communication commitments. When issues arise, address them transparently and promptly.

Strategy 5: Continuous Improvement Through Lessons Learned

The best project managers don’t just complete projects—they learn from them. Each project provides valuable insights that can improve future performance.

Capturing Lessons Throughout the Project

Don’t wait until the end to start documenting lessons. Implement a continuous learning process:

- Regular team reflections (weekly or monthly)

- Issue logs with resolution notes

- Risk response effectiveness tracking

- Innovation and improvement idea collection

Simple questions like “What went well this week?” and “What could we improve?” can yield valuable insights when asked consistently.

Conducting Effective Post-Project Reviews

At project completion, conduct a thorough review using this structured approach:

| Review Area | Questions to Ask | Documentation Method |

|---|---|---|

| Schedule Performance | Were milestones met? What caused delays? Which activities took less time than expected? | Variance analysis with root causes |

| Cost Management | Were estimates accurate? Which items exceeded budget? Where did we save money? | Budget comparison spreadsheet |

| Quality Outcomes | Did we meet specifications? Were there rework issues? How effective were our QA/QC processes? | Quality incident log with solutions |

| Team Performance | How well did teams collaborate? Were roles clear? Did we have the right skills? | Team survey and facilitated discussion |

Make sure these sessions don’t become blame games. Focus on systemic issues rather than individual mistakes, and always emphasize the goal of improvement rather than criticism.

Creating Organizational Knowledge

Individual learning only helps if it becomes organizational knowledge. Consider:

- Creating a searchable lessons-learned database

- Developing case studies from significant projects

- Updating templates and processes based on findings

- Sharing insights through lunch-and-learns or internal newsletters

When I started at my first engineering firm, I was amazed at how many projects encountered the same preventable issues. The problem wasn’t that people weren’t learning—it was that the organization wasn’t capturing and sharing that learning effectively.

Personal Development as a Project Manager

Finally, commit to your own professional growth:

- Seek feedback on your management approach

- Stay current with industry trends and best practices

- Pursue relevant certifications (PMP, CCM, LEED AP)

- Build relationships with mentors and peers

At Colleges to Career, we offer specialized video lectures on project management techniques specifically tailored for engineering students transitioning to professional roles.

Key Takeaway: Make learning a deliberate process, not an afterthought. Document lessons systematically, share knowledge widely, and commit to continuous personal development. Each project should make you and your organization more effective at managing the next one.

Frequently Asked Questions

How does project management work in construction?

Construction project management applies standard project management principles to the specific challenges of building physical structures. The process typically follows these steps:

- Pre-construction planning: Defining scope, creating estimates, developing schedules, and securing permits

- Resource coordination: Mobilizing labor, equipment, and materials according to the schedule

- Progress monitoring: Tracking actual vs. planned performance for schedule and cost

- Quality control: Ensuring work meets specifications and building codes

- Safety management: Implementing and enforcing safety protocols

- Change management: Processing modifications to scope, schedule, or budget

- Closeout: Completing punch lists, obtaining occupancy permits, and transitioning to operations

Construction project management requires balancing the classic “triple constraint” of scope, time, and cost while maintaining quality and safety standards.

What skills are essential for project management in civil engineering?

Successful civil engineering project managers combine technical knowledge with management capabilities:

- Technical understanding: Ability to comprehend engineering principles and construction methods

- Planning and organization: Creating realistic schedules and resource allocations

- Financial management: Developing and tracking budgets, managing cash flow

- Risk assessment: Identifying potential issues and developing mitigation strategies

- Communication: Clearly conveying information to diverse stakeholders

- Leadership: Motivating teams and making decisions under pressure

- Problem-solving: Finding creative solutions to unexpected challenges

- Negotiation: Working with contractors, suppliers, and stakeholders to resolve conflicts

- Regulatory knowledge: Understanding permits, codes, and compliance requirements

- Digital literacy: Proficiency with project management software and BIM

The most effective project managers continually develop both their technical and interpersonal skills.

How can I implement BIM on my projects?

Implementing BIM effectively requires a strategic approach:

- Start with clear objectives: Define what you want to achieve with BIM (visualization, clash detection, quantity takeoffs, etc.)

- Establish BIM requirements: Create a BIM Execution Plan (BEP) that outlines modeling standards, level of detail, and information exchange protocols

- Ensure team capability: Verify that all team members have the necessary skills and software

- Begin with pilot projects: Start with smaller, less complex projects to build capability

- Plan for integration: Determine how BIM will connect with other systems (scheduling, cost estimating, facility management)

- Measure results: Track benefits like reduced RFIs, fewer change orders, and improved coordination

Remember that BIM is more than software—it’s a collaborative process that requires changes to traditional workflows.

What are the biggest challenges in civil engineering project management?

Common challenges include:

- Scope creep: Expanding requirements without corresponding adjustments to schedule or budget

- Unrealistic schedules: Pressure to commit to aggressive timelines despite known risks

- Resource constraints: Limited availability of skilled labor, specialized equipment, or materials

- Communication breakdowns: Information silos between design, engineering, and construction teams

- Regulatory hurdles: Navigating complex permitting and approval processes

- Weather and site conditions: Dealing with uncontrollable environmental factors

- Stakeholder management: Balancing competing interests from clients, communities, and authorities

Addressing these challenges requires proactive planning, clear communication, and agile response to changing conditions.

Conclusion: Bringing It All Together

Effective project management in civil engineering combines technical knowledge with strategic thinking and people skills. By mastering the five strategies we’ve discussed—understanding the project lifecycle, leveraging technology, embracing sustainability, excelling at communication, and committing to continuous improvement—you’ll be well-equipped to deliver successful projects.

Remember that project management isn’t just about following processes—it’s about leadership and decision-making in complex, dynamic environments. The best project managers are those who can adapt their approach to each project’s unique challenges while maintaining focus on fundamental principles.

As you continue your journey from college to career in civil engineering, invest time in developing both your technical expertise and your project management capabilities. These complementary skill sets will make you invaluable to employers and set you up for long-term success in the industry.

Ready to take your project management skills to the next level? Check out our comprehensive interview preparation resources that include practice questions specifically for project management roles in engineering fields.