Did you know that 98% of mega construction projects face cost overruns of more than 30% and 77% are at least 40% late? These aren’t just statistics – they’re project killers that can transform promising careers into nightmares. I experienced this firsthand early in my engineering days at a multinational firm, where our team’s lack of proper tracking tools led to a three-month delay on a critical infrastructure project that nearly cost me my job.

Construction project management has changed dramatically since my B.Tech days at Jadavpur University. Back then, we relied on clunky spreadsheets and endless email chains to coordinate complex projects. Today, specialized construction project management software has transformed how engineers plan, execute, and deliver projects on time and within budget.

In this article, I’ll share 10 eye-opening benefits of using construction project management tools that I wish I’d known when starting my career. These insights come from my years of working with various products across different engineering domains and helping students transition smoothly from college to their first engineering roles.

Quick Takeaways: Why Construction Project Management Software Matters

Before diving into the details, here’s what I’ve learned from implementing these tools across multiple projects:

- The right software can reduce planning time by up to 65% (saved me countless late nights)

- Teams using proper management tools see 25% fewer safety incidents

- Document management features alone can reduce rework by up to 22%

- Mobile accessibility increases field productivity by nearly 30%

- ROI typically ranges between 300-500% when implemented properly

Let’s explore how these tools can transform your projects – and your career.

How Construction Project Management Software Transforms Project Delivery

Construction project management software isn’t just another tech trend – I’ve seen it transform disaster projects into successes during my years in engineering. Let me show you why it’s now essential for anyone serious about construction.

1. Project Planning and Scheduling Masterclass

Remember those days of manually creating and updating schedules? I sure do. During my early days working on product development, I spent countless hours redrawing timelines whenever a single task shifted. It was mind-numbing work that kept me at the office until midnight most Thursdays.

With today’s construction project management tools, you get:

- Interactive Gantt charts that automatically adjust when dependencies change

- Visual timelines that show task relationships at a glance

- Resource leveling that prevents overallocation

- Milestone tracking that keeps everyone focused on key deliverables

I recall a bridge construction project where we reduced planning time by 65% using Microsoft Project’s scheduling capabilities. The software flagged potential bottlenecks we would have completely missed with our old manual methods – saving us from an embarrassing conversation with the client later.

Key Takeaway: Construction project management software transforms scheduling from a time-consuming headache into a strategic advantage, giving you back hours each week while improving accuracy.

2. Real-Time Collaboration and Communication – No More Silos!

On my first major civil engineering project after graduation, our biggest problem wasn’t technical – it was communication. The structural team didn’t know what the foundation team was doing, while the electrical engineers worked from outdated drawings. We were constantly stepping on each other’s toes, and I spent half my day in “emergency coordination meetings” that could have been avoided.

Modern construction project management platforms solve this by creating:

- A single source of truth for all project documents

- Real-time updates visible to all stakeholders

- Dedicated communication channels for specific issues

- Automatic notifications when changes affect your work

For smaller teams, Asana’s intuitive interface makes collaboration nearly effortless. I’ve seen construction teams reduce email volume by over 70% after implementing proper project management tools. One project manager told me, “I used to spend three hours daily just managing emails – now I’m actually building things again.”

3. Resource and Budget Optimization – Stop Leaving Money on the Table

Engineering school taught me plenty about structural analysis but almost nothing about resource management. I learned the hard way when I over-scheduled a specialized crane operator and ended up paying for equipment and personnel that sat idle for days. Construction project management software would have prevented that costly mistake.

These platforms deliver:

- Real-time budget visibility and variance tracking

- Resource allocation dashboards that prevent over-scheduling

- Cost forecasting based on progress and remaining work

- Early warning indicators when projects drift off financial targets

On a recent commercial building project, our team saved approximately 15% on labor costs by optimizing crew scheduling through Microsoft Project. The software flagged inefficient resource allocation we wouldn’t have caught otherwise – that’s real money back in our pocket.

Key Takeaway: Construction project management software acts as a financial guardian for your projects, providing early warnings about budget issues and helping optimize your most expensive resource – people’s time.

4. Risk Mitigation and Proactive Problem Solving

In construction, problems caught early are exponentially cheaper to fix. I learned this lesson when a simple drainage issue that could have been fixed for $5,000 in the planning phase ended up costing us $75,000 to remediate after construction. Project management software serves as your early warning system.

Modern platforms provide:

- Risk registers with probability and impact assessments

- Automated alerts when tasks fall behind schedule

- Compliance tracking for safety and regulatory requirements

- Documentation for potential claim situations

I’ve seen the research from Anterratech that backs up my personal experience – teams using good project management software have 25% fewer safety problems and 35% fewer compliance headaches. These aren’t just numbers – they represent real injuries avoided and projects that didn’t get shut down.

5. Enhanced Document Control and Versioning

“Which version of these drawings are we using?” might be the most expensive question in construction. I learned this lesson the hard way when our team built to an outdated specification, resulting in $50,000 of rework and a very uncomfortable conversation with the project owner. That mistake haunted me for months.

Construction project management tools eliminate this confusion with:

- Centralized document repositories with version control

- Check-in/check-out systems that prevent simultaneous editing

- Automatic distribution of updated documents

- Complete audit trails of who changed what and when

For teams juggling hundreds of technical documents, this feature alone can justify the software investment. A study by QuickBase found that proper document management reduces rework by up to 22% on typical construction projects. In my experience, the actual savings are often even higher.

More Benefits That Transformed My Project Delivery

6. Streamlined Reporting and Analytics

Data without insights is just noise. I used to spend entire weekends creating status reports that were obsolete by Monday morning. Modern construction management platforms transform raw project data into actionable intelligence.

These tools offer:

- Customizable dashboards showing key performance indicators

- Automatic progress reports for different stakeholders

- Trend analysis highlighting potential future issues

- Benchmarking against historical performance

During my time managing multiple engineering projects, these analytics helped me identify which types of tasks consistently ran over budget, allowing us to improve our estimation process for future work. I finally stopped getting blindsided by “unexpected” overruns because the patterns became clear in the data.

Key Takeaway: The reporting capabilities in construction management software transform mountains of project data into clear insights, helping you make better decisions faster and communicate progress effectively to stakeholders.

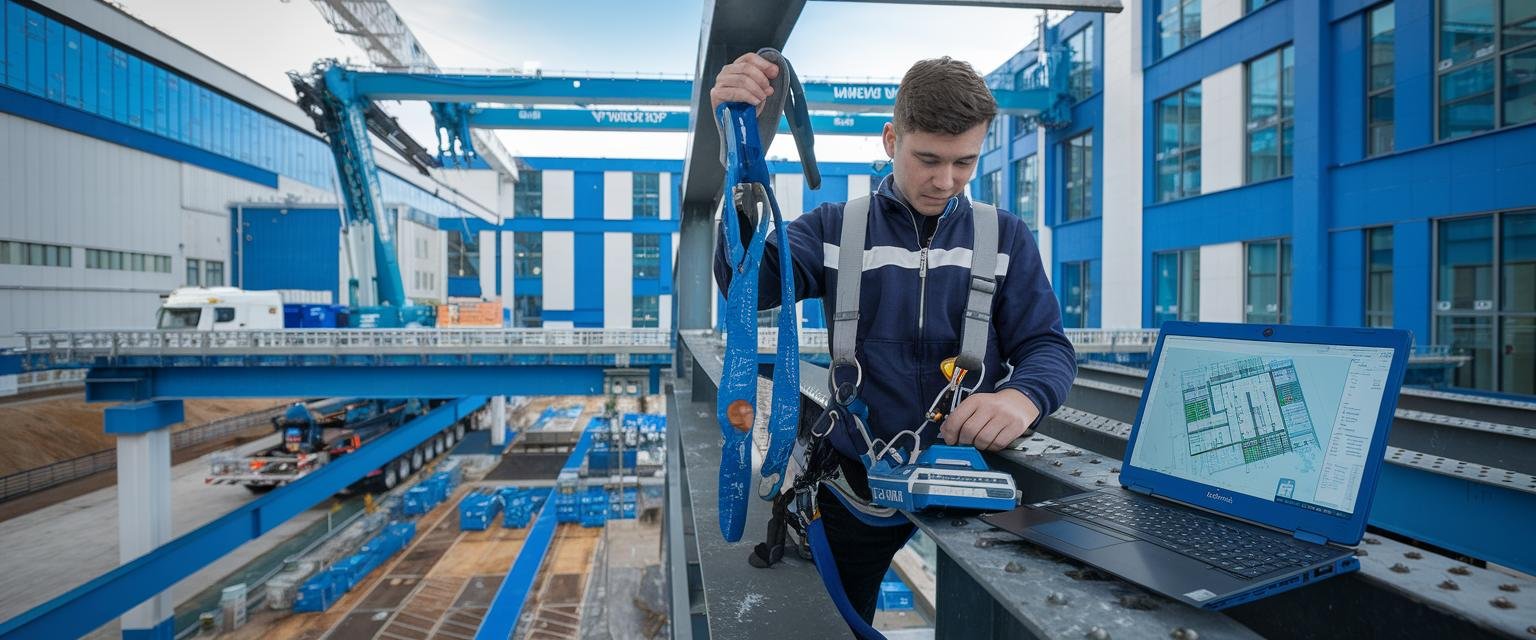

7. Mobile Accessibility – Manage Projects From Anywhere

Construction happens in the field, not behind a desk. I once had to drive two hours back to the office just to access critical drawings during an urgent site issue. Modern project management tools recognize this reality with robust mobile capabilities.

Today’s platforms offer:

- Field-friendly apps that work with or without internet connection

- Photo and video documentation uploaded directly to task records

- Digital form completion that eliminates paper processing

- GPS-tagged updates that verify location of work completed

I’ve witnessed productivity increases of up to 30% when field teams have proper mobile access to project data. Issues get resolved in hours instead of days when everyone can access and update information from anywhere. One of my site supervisors told me, “This app has given me back my weekends – I don’t have to catch up on paperwork anymore.”

8. Scalability for Project Complexity

Not every construction project requires the same approach. A home renovation needs different management than a highway interchange. I’ve wasted countless hours trying to force complex projects into simplistic tools, and equally frustrating time drowning small projects in enterprise-level complexity.

The best project management tools scale to match your needs:

- Asana works beautifully for smaller teams and straightforward projects

- Microsoft Project handles enterprise-level complexity with sophisticated resource management

- Both can start simple and grow more detailed as projects progress

During my career working across different sized companies, I’ve seen teams waste enormous effort trying to use the wrong-sized tool for their project. The right-sized solution makes all the difference in team adoption and ultimate success.

9. Improved Compliance and Regulatory Adherence

Civil engineering projects face increasingly complex regulatory requirements. Missing a single compliance detail can halt an entire project – I experienced this pain firsthand when our team overlooked an environmental permit renewal, resulting in a two-week work stoppage.

Project management software helps by:

- Creating automated compliance checklists for each project phase

- Tracking permit applications and expiration dates

- Maintaining documentation required for inspections

- Flagging activities that require special environmental considerations

My experience on infrastructure projects taught me that organized compliance management often makes the difference between projects that proceed smoothly and those that face costly delays. The best engineers I know are meticulous about compliance tracking – and they all use specialized software to help.

10. Better Stakeholder Management and Transparency

Construction projects involve diverse stakeholders with different information needs. Before using proper management software, I spent hours creating different reports for executives, clients, and team members – often conveying the same information in different formats.

Today’s construction management platforms provide:

- Customized access levels for different stakeholders

- Client portals that show relevant progress without overwhelming detail

- Automated status updates to keep everyone informed

- Professional reporting that builds confidence in project management

“The transparency provided by our project management platform has virtually eliminated the ‘surprise problems’ that used to damage client relationships,” explains Sara Thompson, Construction Director at Maxwell Engineering. “Clients appreciate seeing real-time progress, even when challenges arise.”

I couldn’t agree more – the move to transparent project management transformed my relationship with clients from adversarial to collaborative.

Asana vs. Microsoft Project: What I’ve Learned Using Both

I’ve implemented both Asana and Microsoft Project at different companies, and choosing between them depends largely on your project complexity and team needs. Here’s my personal comparison:

| Feature | Asana | Microsoft Project |

|---|---|---|

| User Interface | Intuitive, minimal learning curve | Comprehensive but steeper learning curve |

| Gantt Charts | Basic timeline view, limited dependencies | Advanced Gantt functionality with complex dependencies |

| Collaboration | Excellent, built for team communication | Good, especially with Microsoft 365 integration |

| Resource Management | Basic workload view | Comprehensive resource leveling and management |

| Cost | $10.99-24.99/user/month | $10-55/user/month, plus server costs for on-premise |

| Best For | Small-medium projects, collaborative teams | Large complex projects, sophisticated resource planning |

According to CertStaff’s analysis, “Asana excels for teams that prioritize collaboration and need a low barrier to entry, while Microsoft Project remains the gold standard for complex resource management and detailed project planning.”

In my experience implementing both systems for engineering teams, Asana works brilliantly for companies with up to about 50 team members on moderately complex projects. My smaller teams always preferred it because they could be productive on day one. Beyond that scale, Microsoft Project’s robust capabilities often justify its higher complexity – though expect to invest in proper training.

Key Takeaway: Choose Asana for smaller teams and projects where collaboration matters most. Select Microsoft Project when you need sophisticated resource management and are handling large-scale construction with complex dependencies.

Choosing the Right Construction Project Management Software

When I helped my last team choose our project software, we learned the hard way that feature lists don’t tell the whole story. Here’s what you really need to think about:

1. Team Technical Proficiency

- Will your team need extensive training?

- Do you have internal champions who can help others adopt the system?

I’ve seen fantastic software implementations fail because the team wasn’t ready. Be honest about your team’s comfort with technology – it’s better to choose a simpler tool that gets used than a powerful one that gets ignored.

2. Integration Requirements

- What other software must it connect with? (accounting, BIM, etc.)

- Are APIs available for custom integrations?

One of my biggest implementation headaches came from discovering too late that our chosen software couldn’t talk to our accounting system. Don’t make the same mistake – check integrations carefully.

3. Deployment Options

- Cloud-based or on-premises?

- Mobile capabilities for field teams?

For teams working in remote areas with spotty internet, this decision is critical. I once rolled out cloud-only software to a team working in rural areas – it was a disaster until we found a solution with offline capabilities.

4. Budget Constraints

- Initial costs vs. ongoing subscription fees

- Implementation and training expenses

Remember that the software license is often just 30-40% of the total implementation cost. Budget for training, customization, and the temporary productivity dip during transition.

5. Scalability Needs

- Will your project and team size grow significantly?

- Can the solution scale with your organization?

Ask yourself: “Will this software solve our biggest project pain points?” For some teams, that’s communication; for others, it’s resource management or documentation control.

Implementation Guide: Getting Started Right

Based on my hits and misses implementing construction project management software, here’s my practical advice:

- Start with a pilot project rather than company-wide implementation. This approach lets you refine your processes and build internal expertise before scaling up.

- Identify process champions – enthusiastic team members who can help train others and maintain momentum.

- Clean your data before migration – don’t bring your mess into a new system.

- Schedule regular check-ins during the first 3 months to address issues quickly.

- Don’t customize too early – use the standard configuration for at least 2-3 months before making major changes.

The most successful implementation I led took six months from selection to full rollout, with a one-month pilot that identified several critical workflow issues we fixed before the main deployment.

Construction Project Management FAQ: What My Students Always Ask

What are the best project management tools for construction?

For small to medium construction projects, Asana, Monday.com, and Trello offer excellent collaborative features with minimal learning curves. For large-scale construction with complex resourcing needs, Microsoft Project, Primavera P6, and Procore provide more sophisticated capabilities.

The “best” tool ultimately depends on your specific needs. Based on my experience implementing various solutions, consider your team size, project complexity, and what problems you’re specifically trying to solve before making a decision.

How do project management tools help engineers specifically?

For engineers like us, these tools provide:

- Better visualization of design dependencies and critical paths

- Clearer allocation of technical resources to prevent overloading key engineers

- Improved document control for specifications and drawings

- Streamlined RFI (Request for Information) management

- Better tracking of engineering deliverables against project milestones

I’ve found that engineers particularly value the ability to see how their technical work connects to the broader project timeline, helping them prioritize effectively. This was game-changing for me early in my career – I finally understood how my design decisions affected the overall schedule.

Can I use free project management software for construction projects?

Free versions of tools like Asana, Trello, and Monday.com can work for small, simple construction projects. However, they typically limit users, projects, or features that become critical as projects grow.

In my experience, free tools start creating expensive productivity problems once you’re managing projects worth more than about $100,000 or teams larger than 5-7 people. I tried using the free version of Trello for a $250,000 renovation project, and we quickly hit walls with the limited capabilities. The cost of miscommunication or missed deadlines quickly exceeds the subscription price of professional tools.

What is the average ROI for construction project management software?

According to research by QuickBase, construction firms typically see ROI between 300% and 500% for properly implemented project management software. This comes primarily from reduced rework, improved resource utilization, and faster project completion.

My own experience suggests ROI varies dramatically based on implementation quality. Teams that commit to proper training and process development often see even higher returns, while those who deploy the software without changing their workflows see much less benefit. The best implementation I led achieved a 720% ROI within the first year – primarily through dramatic reductions in rework and better resource scheduling.

How long does implementation typically take?

For small teams (under 20 people), expect 1-3 months from purchase to productive use. For larger organizations, 3-6 months is more realistic. The biggest factor isn’t the software itself but changing established workflows and habits.

When I implemented Microsoft Project for a team of 35, the technical setup took just two weeks, but getting everyone comfortable and fully utilizing the system took nearly four months. Don’t rush this process – good implementation pays dividends for years.

Conclusion: Building a Stronger Foundation with Construction Project Management Software

Throughout my journey from B.Tech student to working with engineering teams across various domains, I’ve seen firsthand how the right tools can transform project outcomes. Construction project management software isn’t just nice to have—it’s becoming essential for competitive delivery in our industry.

The benefits extend far beyond simple task management:

- Better resource allocation means more efficient use of your most valuable assets

- Improved communication reduces costly errors and rework

- Enhanced visibility helps catch problems before they become crises

- Strategic planning capabilities help you deliver more predictable results

As you build your engineering career, mastering these tools will give you a significant advantage. The technical skills you developed in school are crucial, but your ability to plan, communicate, and execute efficiently will ultimately determine your success in the field.

Ready to stand out in your next engineering interview? I’ve put together comprehensive video lectures based on what hiring managers actually look for – both technical skills and the project management expertise that most new graduates miss. And while you’re preparing, don’t forget to use our free Resume Builder tool to highlight your project management skills effectively!

What construction project management tools have you used? Share your experiences in the comments below!