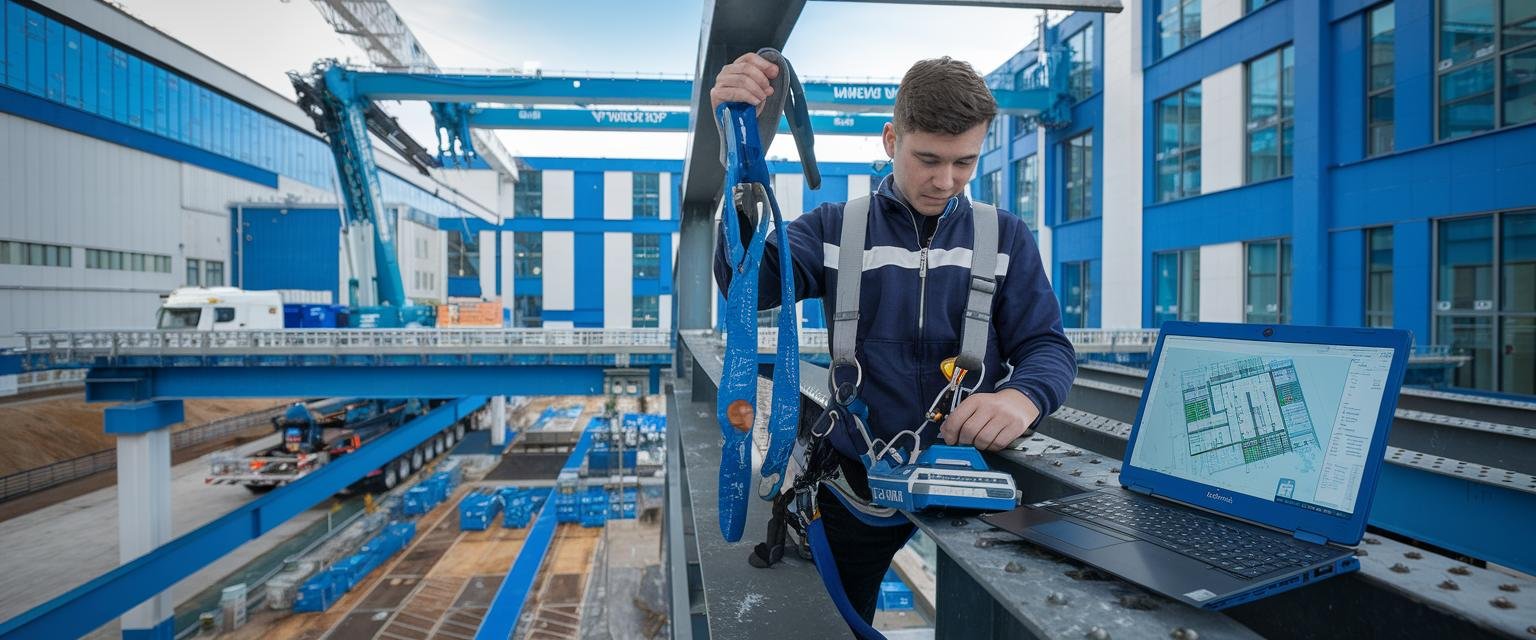

After getting my B.Tech degree from Jadavpur University, I knew how to design structures but had no clue how to manage projects. My first job? I was suddenly sitting in coordination meetings for a huge bridge project, completely lost! It was like learning to swim by being pushed into the deep end.

This experience taught me something crucial: technical skills alone don’t build successful careers in engineering. Project management expertise is equally important, especially if you want to climb the ladder.

Becoming a Certified Project Manager can transform your engineering career. Whether you’re a recent graduate or a mid-career professional, these certifications provide the structure, methodology, and credibility that engineering projects demand.

In this post, I’ll guide you through the most valuable project management certifications for civil engineers, how they benefit your career trajectory, and how to choose the one that’s right for you.

Why Project Management Certifications Matter for Engineers

Let’s be honest – civil engineering is a field where things can go spectacularly wrong if managed poorly. Remember the infamous Millennium Bridge in London that had to close just two days after opening because it wobbled too much? That wasn’t a failure of engineering knowledge but of project execution.

Project management certifications offer several concrete benefits:

- Salary boost: Certified project managers earn 20% more on average than their non-certified peers, according to the Project Management Institute’s Salary Survey.

- Career advancement: When I review resumes at my company, candidates with relevant certifications instantly move to the top of the pile. They signal commitment and specialized knowledge.

- Improved project outcomes: Certified project managers bring standardized approaches that reduce errors, control costs, and keep timelines on track.

- Competitive edge: With engineering becoming more globalized, certifications provide universal recognition of your abilities.

Yes, getting certified takes time and money. When I pursued my PMP certification, I invested about $1,500 and three months of weekend study sessions. Was it worth it? Absolutely. Within six months, I secured a position that paid $15,000 more annually.

Becoming a Certified Project Manager: Top Options for Civil Engineers

PMP (Project Management Professional)

Want the most respected project management certification? That’s the PMP (Project Management Professional). It’s like a global passport that tells employers you know how to lead projects the right way. For us civil engineers, it opens doors everywhere.

When I applied for my PMP, I needed:

- 36 months of project management experience

- 35 hours of project management education

- A four-year degree

The exam itself covers five process groups: initiating, planning, executing, monitoring and controlling, and closing. It tests your knowledge through 180 questions over a four-hour period.

For civil engineers, PMP certification is particularly valuable when managing infrastructure projects. I still remember applying PMP principles when I led a municipal water treatment facility upgrade – I had a clear framework for managing each phase, from initial planning through execution to final handover, which kept the project on track despite material shortages and design changes.

One of my college friends, Rajat, obtained his PMP certification three years after graduating. Within six months, he moved from a site engineer position to managing a team of 15 engineers on a highway development project, with a 35% salary increase.

Other Project Management Certifications

While PMP is the most recognized, other certifications might be more suitable depending on your career stage and location:

- PRINCE2 (PRojects IN Controlled Environments): Popular in the UK and Europe, PRINCE2 is process-based and focuses on dividing projects into manageable stages. It’s particularly useful for civil engineers working on government infrastructure projects where rigid control procedures are required.

- CAPM (Certified Associate in Project Management): If you don’t yet qualify for the PMP, the CAPM is a great starting point. It requires fewer prerequisites and provides a solid foundation in project management principles.

- PgMP (Program Management Professional): For experienced engineers looking to manage multiple related projects, PgMP certification demonstrates your ability to coordinate resources and align outcomes across complex programs.

| Certification | Best For | Approximate Cost | Experience Required |

|---|---|---|---|

| PMP | Experienced professionals ready for leadership | $555 (non-members) | 36 months with degree, 60 months without |

| PRINCE2 | UK/European projects, government work | $400-$800 | None (Foundation), Project experience (Practitioner) |

| CAPM | Early-career professionals | $300 (non-members) | High school diploma and 23 hours of education |

| PgMP | Senior engineers managing multiple projects | $800 (non-members) | 4 years of project management + 4 years program management |

Essential Civil Engineering-Specific Certifications

While project management certifications enhance your leadership skills, civil engineering-specific certifications establish your technical authority. Let’s explore the most valuable ones:

PE (Professional Engineer License)

The PE license is arguably the most important credential for civil engineers in the United States. It grants you the legal authority to sign and seal engineering documents and officially take responsibility for engineering work.

Requirements typically include:

- An ABET-accredited engineering degree

- Passing the Fundamentals of Engineering (FE) exam

- 4+ years of progressive engineering experience

- Passing the Professional Engineering (PE) exam

The PE license significantly impacts your earning potential and career mobility. According to the National Society of Professional Engineers, licensed engineers can earn up to 25% more than their non-licensed counterparts over a lifetime.

When I worked with a municipal project team on a flood control system, I noticed that engineers with PE licenses were the final decision-makers on critical design issues. They also commanded higher salaries and had more job security, especially when budget cuts came around.

Regional Engineering Certifications

Engineering certifications vary by country:

- P.Eng (Canada): Similar to the PE in the US, this designation requires an accredited degree, work experience, and passing the Professional Practice Examination.

- ICE (Institution of Civil Engineers), IStructE (Institution of Structural Engineers), and MCIOB (Member of the Chartered Institute of Building) in the UK: These provide professional recognition and are often required for senior positions.

Research the specific requirements in your region – I’ve seen talented engineers miss opportunities simply because they didn’t have the locally recognized certification.

Emerging Certifications: BIM and Specialized Skills

The civil engineering field is constantly evolving. Staying ahead of technological trends through specialized certifications can make you invaluable to employers.

BIM (Building Information Modeling) Certification

BIM has revolutionized how civil engineering projects are designed, visualized, and managed. According to a report by Dodge Data & Analytics, 76% of contractors report that BIM reduces errors and improves project outcomes.

Popular BIM certifications include:

- Autodesk Certified Professional in Revit

- Bentley Institute’s BIM certification

- BuildingSMART Professional Certification

When my team adopted BIM for a commercial development project in Bangalore, our engineers with BIM certifications became the go-to resources. They helped us catch a major structural-mechanical clash before construction began, which would have cost us at least 30 lakhs to fix later. By the end of the project, we had reduced rework by nearly 40%.

Still confused about how BIM works in real projects? I’ve created several video walkthroughs showing exactly how we used it to solve problems on my commercial development project. Check out these step-by-step guides in our video lecture series.

Specialty Certifications

Civil engineering encompasses numerous specialties, each with its own certifications:

- Structural Engineering: Structural Engineering Certification Board (SECB) certification

- Geotechnical Engineering: Academy of Geo-Professionals (AGP) certification

- Transportation Engineering: Professional Traffic Operations Engineer (PTOE) certification

- Environmental Engineering: Board Certified Environmental Engineer (BCEE)

A former classmate specialized in environmental engineering with a BCEE certification and now leads sustainability initiatives for major infrastructure projects at twice the salary of peers who remained generalists. During our last chat, he mentioned that his specialized certification was the deciding factor that got him the job over candidates with more years of experience.

Choosing the Right Certification: Factors to Consider

With so many certification options, how do you pick the right one? Ask yourself these questions:

Eligibility Requirements

Before setting your heart on a certification, check if you meet the prerequisites:

- Education: Most high-level certifications require an accredited engineering degree.

- Experience: PMP requires 36 months of leading projects with a degree, while PE typically requires 4 years of progressive experience.

- Other Requirements: Some certifications require recommendations or membership in professional organizations.

I once spent months studying for a specialized structural certification only to discover I needed two more years of specific experience to qualify. Don’t make my mistake – check the requirements first!

Cost and Duration

Certification is an investment in both time and money:

- Exam Fees: Range from $300 for CAPM to $800+ for PgMP

- Training Costs: Preparation courses typically cost $1,000-$2,500

- Time Commitment: Most certifications require 100-200 hours of study

When I pursued my PMP, I set aside two hours each evening and most of my weekends for three months. It was intense juggling study with my full-time job on the metro extension project, but having a structured study plan made it manageable. I created flashcards for my daily commute and joined weekend study sessions with colleagues.

Career Goals

Where do you want to be in five years? Project manager? Technical specialist? Department head? Figure that out first, then pick the certifications that will get you there. Create your own certification roadmap – it’s the fastest way to level up your engineering career.

- Want to manage large infrastructure projects? PMP might be your best bet.

- Aiming to become an authority in structural design? PE with structural focus is essential.

- Looking to specialize in sustainable development? Consider LEED AP or BCEE.

Tips for Certification Preparation

Getting certified isn’t easy, but these strategies will improve your chances of success:

Study Resources

- Official Guides: Always start with the certification body’s official materials. For PMP, the PMBOK Guide is essential.

- Training Courses: Consider in-person or online courses. I found Project Management Academy’s boot camp extremely helpful for PMP.

- Study Groups: Form a group with colleagues pursuing the same certification. We created a WhatsApp group for weekend study sessions at a local coffee shop that kept us accountable.

Exam Strategies

- Practice Questions: Complete at least 1,000 practice questions before taking the PMP exam. I used PM PrepCast and scored 30% higher on sections I had practiced extensively.

- Time Management: Develop a strategy for pacing yourself during the exam. I allocated 1 minute per question, flagging difficult ones to revisit later.

Financial Assistance

- Employer Reimbursement: Many companies cover certification costs. I successfully negotiated full reimbursement by demonstrating how my PMP certification would benefit upcoming projects. I created a one-page document showing how specific PMP methodologies would solve problems we were facing on our current bridge project.

- Scholarships: Organizations like PMI offer scholarships for certification costs. The American Society of Civil Engineers also provides education grants.

Need help highlighting your new certifications on your resume? Our resume builder has specific sections designed to showcase your certifications in a way that catches employers’ attention.

Taking Your Engineering Career to the Next Level with Certified Project Management

Becoming a Certified Project Manager transforms your engineering career in multiple ways. It expands your skillset beyond technical expertise into the realm of coordinating people, processes, and resources. This combination makes you incredibly valuable to employers.

I started as a technical contributor with strong engineering knowledge but limited leadership skills. Project management certification changed how senior leaders viewed me – I became someone who could not only design solutions but also ensure they were delivered on time and within budget.

For civil engineers specifically, the combination of technical credentials like the PE license with project management certifications like PMP creates a powerful professional profile. You understand both the engineering requirements and how to execute complex projects successfully.

On my last major project – a multi-story commercial complex – my dual expertise helped me bridge communication gaps between structural engineers and project stakeholders. When design changes threatened to delay the project by weeks, I used my project management skills to resequence activities while ensuring engineering standards weren’t compromised.

Are you ready to show off your new project management skills in interviews? I’ve collected all the toughest questions employers asked me about managing engineering projects. Practice with our engineering project management interview questions and walk in with confidence.

Frequently Asked Questions About Engineering Certifications

What are the best certifications for civil engineers?

The most valuable certifications for civil engineers combine technical authority with management expertise. The PE license establishes your engineering credentials, while PMP certification demonstrates your project management capabilities. For emerging professionals, CAPM offers a starting point in project management, while specialized certifications in areas like BIM, structural engineering, or environmental engineering can differentiate you in specific sectors.

How do certifications benefit your career?

Certifications provide multiple benefits: increased earning potential (20-25% higher salaries), improved job prospects, faster career advancement, greater job security, and enhanced professional credibility. They also expand your professional network through certification organizations and demonstrate your commitment to continuous learning.

How long does it take to get certified?

Timeframes vary by certification:

- PMP: 3-6 months of preparation assuming you meet experience requirements

- PE: 4+ years (including required work experience after graduation)

- CAPM: 1-3 months of preparation

- BIM certifications: 1-2 months for basic certifications

How much does it cost to get certified?

Costs include exam fees, preparation materials, and potential courses:

- PMP: $555 exam fee + $1,000-$2,000 for preparation

- PE: $375 exam fee + $1,000-$1,500 for preparation

- CAPM: $300 exam fee + $500-$1,000 for preparation

- BIM certifications: $200-$500, depending on the specific certification

Are there any prerequisites for certification?

Most professional certifications have prerequisites:

- PMP requires 36 months of project management experience with a degree, or 60 months without

- PE requires an engineering degree, passing the FE exam, and 4+ years of experience

- CAPM requires a high school diploma and 23 hours of project management education

- Specialty certifications typically require relevant experience in that specific field

Which is better: PMP or PE for a civil engineer?

They serve different purposes and ideally, you should pursue both. PE establishes your technical authority and is legally required to sign off on engineering documents. PMP demonstrates your ability to lead projects successfully. Early in your career, focus on PE to establish technical credentials. Mid-career, add PMP to move into management roles.

How can I convince my employer to pay for my certification?

Create a business case that outlines:

- Specific benefits to current/upcoming projects

- ROI in terms of improved processes or outcomes

- Industry benchmarks showing the value of certified professionals

- A commitment to stay with the company for a certain period after certification

I secured employer funding by proposing to implement standardized project management processes across our department after obtaining my certification. I showed how this would save time during handovers and create consistent documentation that reduced errors.